HUEVO 200 Spectrometer

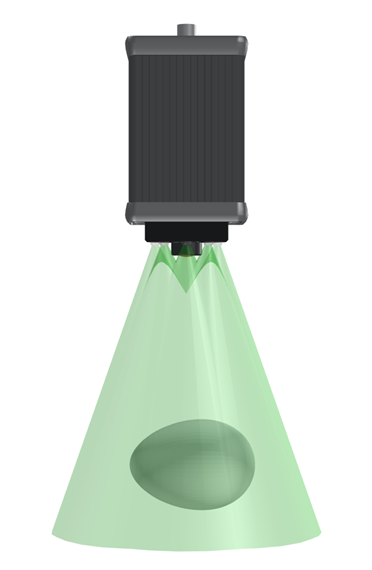

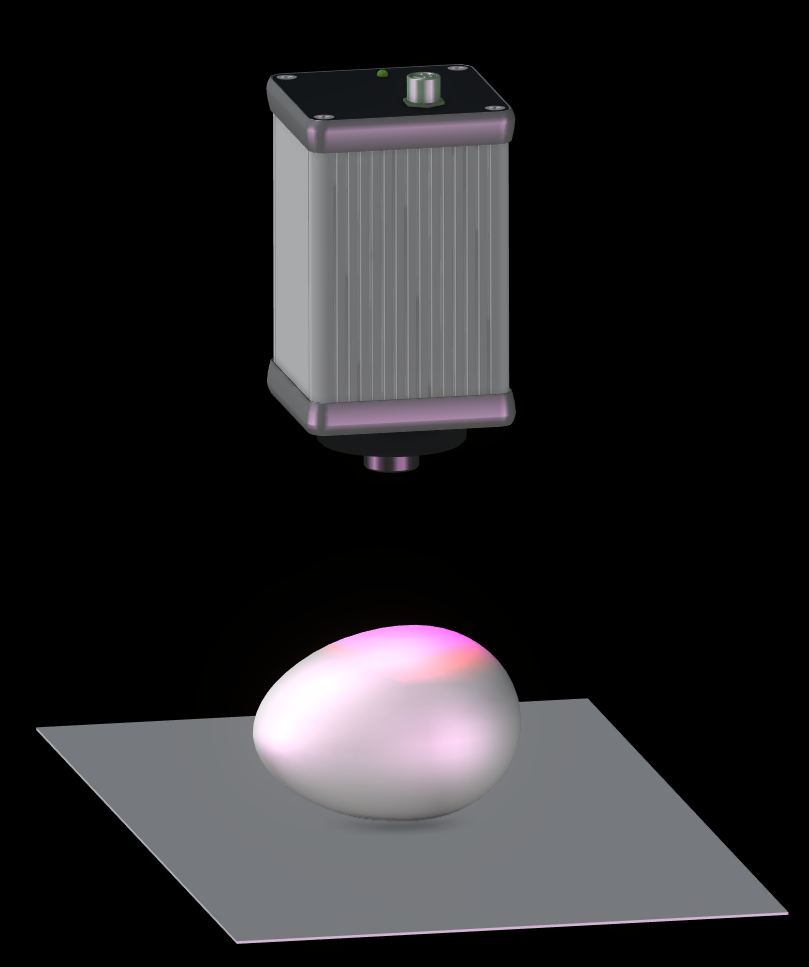

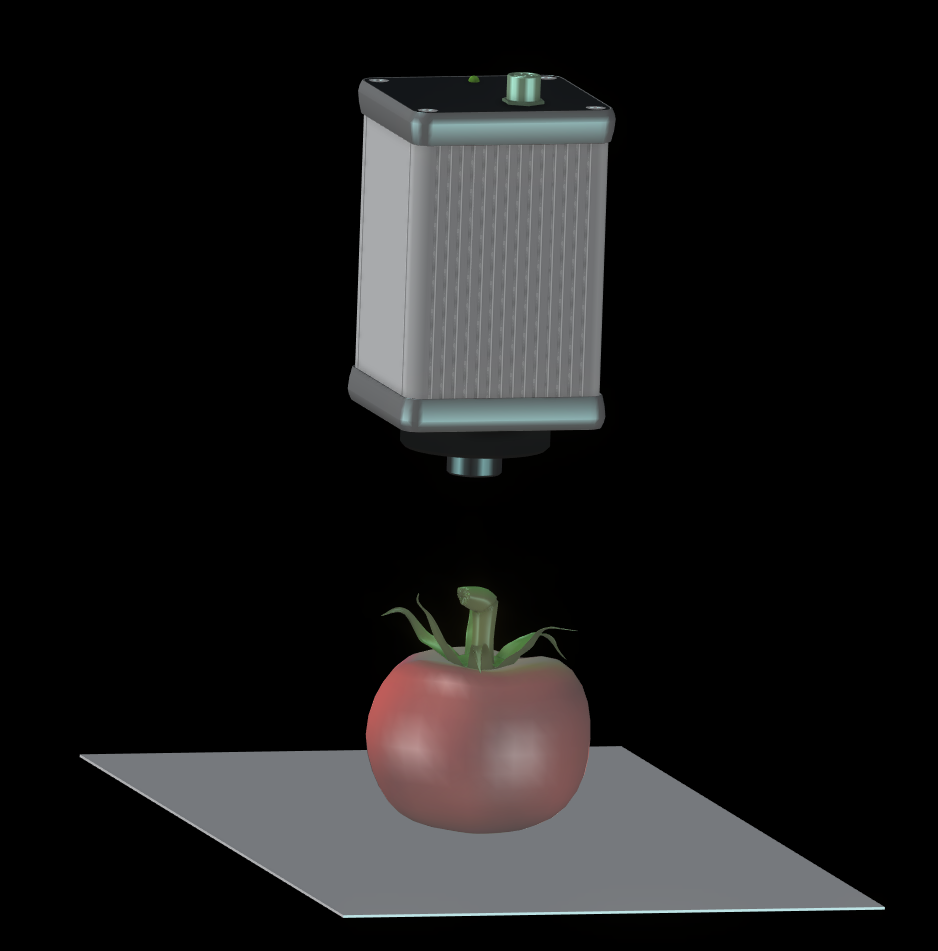

The HUEVO-200 spectrometer is an industrial device that determines the light reflectance of each of the eight wavelengths of light from the tested object. Its primary application is to assess food quality, including eggs, fruits, and some vegetables (e.g., peppers and tomatoes).

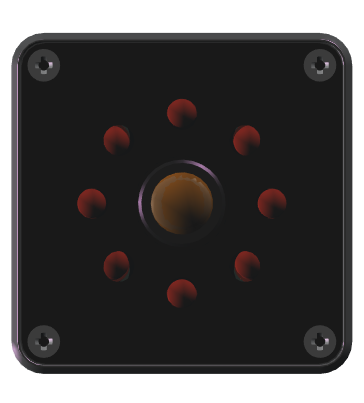

The device works based on the method of reflection spectrometry in the light band from the near ultraviolet to the near-infrared. It contains eight separate light emitters with well-defined colors and a silicon receiving detector operating in the required light wavelength range.

Successive switchable emitters allow the object to be illuminated with successive colors of light and an eight-position light reflection spectrograph for individual colors to be obtained. Specialized software using artificial intelligence algorithms, trained on selected types of tested objects, allows for quick and accurate determination of the required parameters on this basis.

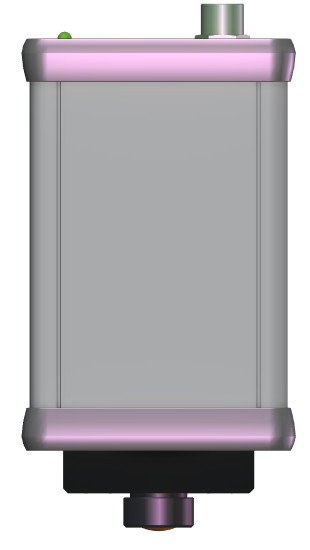

HUEVO-200 spectrometer is designed for use in the food industry. It is built in a small metal housing with IP-67 tightness and dimensions of 57x57x87 mm, as shown in the figure below.

|  |  |  |

The device is connected to the controller via an RS-485 interface (M8 4p connector), allowing reliable data transmission over distances up to 250 m via typical twisted-pair cables. The same cable transmits the power supply to the photometer. One controller can operate up to 8 photometers and control up to 8 executive automation components.

The HUEVO-200 uses a built-in microcomputer with 133MHz ARM cores, which provides fast measurement and the ability to perform spectrograph measurements at up to 50Hz. This makes it possible to work on egg grading belts, for example.

The spectrometer controller can be a specialized industrial computer with an appropriate interface (ordered separately). We also provide complete dedicated controllers with software designed to test individual types of tested food.

|  |

One application of the solution could be detecting eggs from hens infected with the Mycoplasma Synoviae pathogen and the visual automatic assessment of eggshell anomalies for mass production applications. Devices adapted to different volumes of egg production are possible, using non-destructive spectral techniques and machine learning and artificial intelligence (AI) algorithms.

The presence of the Mycoplasma Synoviae pathogen in poultry flocks, mainly those focused on producing table and/or reproductive eggs, poses a serious threat to production. Eggshells from laying hens infected with this pathogen are characterized by reduced mechanical parameters, i.e., thickness, density, and fragility, resulting in increased waste due to mechanical damage during collection, packaging, and transport. On the other hand, young obtained from eggs intended for reproductive purposes from hens infected with MS are characterized by disturbed development and, to a substantial degree, are predestined for utilization.

In addition, the MS infection that spreads rapidly in the herd is difficult to control. It requires pharmacological intervention and continuous monitoring of the herd’s health. Detection of infection in layers at an early stage of development in the flock is crucial to limit the pathogen’s impact, slow down its spread, and identify infected individuals. This minimizes losses incurred by breeders, who are forced to exterminate the herd if they intervene too late.

Currently, hens and/or eggs are being observed. Frequent alarm factors are visible infiltrations or discoloration on the shell and increased egg waste caused by mechanical damage. In such a case, a specialist examination of the material taken directly from the hen should be performed. However, most eggs from infected hens do not bear stigmas that can be detected during a standard visual inspection.

The device’s essence is the rapid detection of pathogen infection in the flock based on egg spectral analysis. Using HUEVO-200 in combination with HUEVO software, you can easily separate such eggs and use them, for example, for industrial purposes.